Products >> Serrated steel grating >>

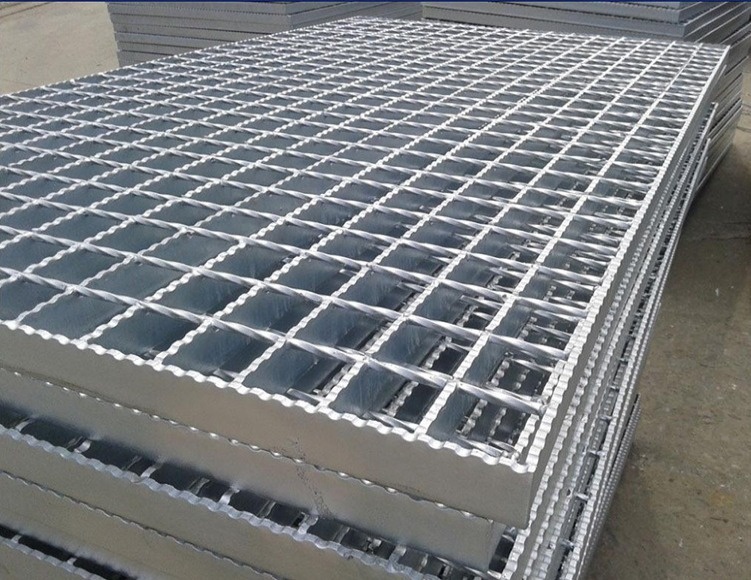

Serrated steel grating

- Product No.:Serrated steel grating

Serrated steel grating

Serrated steel grating is welded from flat steel with one side serrated. In addition to the characteristics and uses of ordinary steel grating, it also has strong anti-skid ability, especially suitable for wet and slippery places, offshore oil platforms, etc.

Serrated steel grating adopts hot-dip galvanizing surface treatment, which has strong anti-rust ability.

Serrated steel grating can be used as a ditch cover and the frame is connected with hinges, which is anti-theft, safe and easy to open.

Toothed steel grating uses high-strength carbon steel, which makes the steel grating have high strength: the strength and toughness are much higher than cast iron, and it can be used in large span and heavy load environments such as docks and airports. This product has large mesh and good drainage: the leakage area is 83.3%, which is more than twice that of cast iron. The product has beautiful appearance: simple lines, silver appearance, modern concept, material saving and investment saving: when it is large span and heavy load, it is lower than cast iron; and it can save the cost of replacing cast iron covers due to theft or crushing.

The raw material composition of toothed steel grating:

Ordinary flat steel: The material is generally Q235. Common models are generally 253 255 303 305 323 325 403 404 405 503 505605 705 and other specifications. We mainly use longitudinally cut flat steel and cut from steel plates. Toothed flat steel:

The model is the same as ordinary flat steel, the difference is that there are uneven tooth marks on one side of the flat steel. Mainly for anti-slip.

Twisted steel: Also called twisted square steel. Generally there are 5x5 6x6 8x8 square steel, twisted steel bars.

Series 1 (spacing 30mm) is a common type of steel grating, which is used in various industrial fields. The center distance of the loaded flat steel of this series of steel grating is 30mm, which meets the requirements of US standards. In the entire steel grating series, it has strong resistance to surface impact. It is widely used in platforms, walkways and drainage ditch covers, stair treads, etc. in power plants, refineries, sewage treatment plants, granaries, chemical plants, highways, airports and docks. Among them, toothed steel gratings can be used in wet and slippery places, especially for offshore oil platforms.

Series 2 (40mm spacing) steel gratings are economical and lightweight, meeting the specifications of fixed platforms, walkways and stairs specified in British standards. They are ideal products for occasions with small spans, even under loads such as transport equipment walkways. They can also be used as warehouse shelves, pavilion panels, trestles, protective fences, sunshades, etc.

Series 3 (60mm spacing) steel gratings are specially developed for mining industry applications. They solve the problem of mineral splashing on the board surface. This series of steel gratings has a nominal size of 50*60mm, allowing most splashing materials to fall through, thereby ensuring the cleanliness and safety of the board surface. This product is often specified for the board surface in the crushing system, the walkway on the conveyor line, and the ball mill, processing plant and operation station, etc.

Toothed steel grating is widely used in various fields such as petroleum, chemical industry, port, electricity, transportation, papermaking, medicine, steel, food, municipal administration, real estate, manufacturing, etc.

Previous Product:Serrated steel grating

Products Category

Contact Us

Name: Jackgong

Tel: +86-18932800930

E-mail: info@xinhengsteelgrating.com;

jackgong@xinhengsteelgrating.com;

Add: Shenzhou City, Hebei Province, China

CHINESE

CHINESE ENGLISH

ENGLISH

Mail inquiry

Mail inquiry